|

Manual

Ultrasonic (UT) Weld Inspection

(Download

Brochure, 100Kb)

Welding

is the most widespread way of connecting metallic mechanic parts of

industrial equipment. The integrity of these connections during

manufacturing as well as during the operation of mechanical equipment is

of critical importance for the safety of the installation. Welding

is the most widespread way of connecting metallic mechanic parts of

industrial equipment. The integrity of these connections during

manufacturing as well as during the operation of mechanical equipment is

of critical importance for the safety of the installation.

The use of

ultrasounds for the integrity inspection of welds is a common practice in

the Industry. The applied technique consists of scanning the weld mass and

the Heat Affected Zone (HAZ) with ultrasonic beams emitted by angle probe

that is moved manually along the lateral region of the weld.

The

detection and sizing of discontinuities is performed by receiving and

evaluating the beam reflected from the discontinuity surface. The

detection and sizing of discontinuities is performed by receiving and

evaluating the beam reflected from the discontinuity surface.

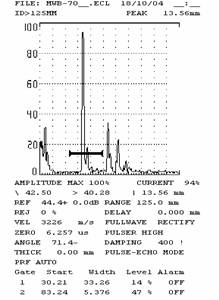

Modern digital

instruments with capability of storing the discontinuity signals are used

for the inspection. Common UT transverse-wave angle probes are used, while

special double-crystal longitudinal-wave probes are used for the

inspection of thick-grained steels (stainless steels).

Advantages

of the method: Advantages

of the method:

-

Quick and direct

results.

-

No protection

against radiation required, neither interruption of other peoples work.

-

In-service

inspection.

-

Inspection of

complex geometry welds with profile analysis of the weld using a PC.

-

Inspections

performed according to international standards ASME, EN etc.

-

Final technical

report that contains position, depth and type information of

discontinuity.

-

Storage of the

discontinuities signals and inspection parameters.

-

Sensitivity in

critical discontinuities detection (e.g. cracking).

Envirocoustics

also provides weld inspection

services using the TOFD (Time Of Flight Diffraction) technique and

weld inspection services using Eddy Currents.

|