|

Guided Ultrasonic Waves Pipe

Inspection

Pipe inspection in the industry can prove

difficult, expensive, time consuming and with limited results using common

NDT techniques, such as UT Thickness. Other inspection techniques such as

PIG may be impossible to apply for practical reasons, such as geometry.

Guided Ultrasonic waves provide a new

solution for pipe inspection. The inspection is a very fast pipe screening

technique which provides information about cross section area change in

the pipe together with precise information a to where along the pipe this

change occurs.

Download

Brochure (828 kb, pdf)

How it works How it works

-

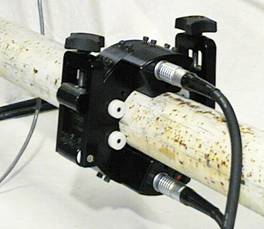

A ring with the

transducers

is placed around the pipe

-

No

couplant is required

-

Usually no surface

preparation required

-

Instrumentation is

fully portable

-

Guided waves are sent

in each direction

-

Data are collected and

stored in the portable instrument

-

Reflections are

analysed and results reported immediately after the test

-

Long sections of pipe

can be examined from one location, e.g. 30m on either side of the ring

Capabilities Capabilities

-

Each test is completed within minutes

including results

-

Can

be performed at elevated temperatures without taking the pipe out of

service up to 125°C.

-

100% of the pipe is

inspected (within the diagnostic length of a test)

-

Pulse echo type

operation provides information on feature position and approximate size

-

Sophisticated analysis

aids interpretation of results

-

Minimum insulation removal for testing

(1m)

-

Difficult-to-inspect

areas (such as roadways) can be screened for defects

|

Small Diameter Pipes

-

Tested using solid

rings

-

For pipes 2 - 8

inches diameter

-

Can be mounted in

less than a minute

-

4

inches clearance needed around pipe

|

Large Diameter Pipes

-

Tested using

inflatable ring

-

For pipes 6 - 48

inches diameter

-

Employ conventional

foot pump to inflate

-

3

inches clearance

needed around most of pipe

|

|

|

|

Two types of waves can be used

|

Torsional

(twisting of

the pipe) |

Longitudinal

(compression of

the pipe) |

|

A typical weld is completely symmetric

and shows up as only a black curve |

A typical corrosion patch is

non-symmetric and is identified by the presence of a red curve |

Target Applications

-

Rapid, full coverage

screening of pipes

-

Especially cost

effective in difficult to access locations

– Sleeved

road crossings

– Corrosion

under insulation

– Wall

penetrations

– Pipe

racks

– Rope

access

-

Can detect local and

general metal loss (greater than 5% of the cross-sectional area). Large

cracks in welds may also be detected. Confirmation of the defect type

and details sizing may be done with other NDT.

|