Rapid

Tube Inspection

using

Eddy Current (ET) or Remote Field (RFT)

methods

(Download

Brochure, 164Kb)

Rapid

Non Destructive (NDT) inspection of tubes can be performed

using electromagnetic (Eddy Current, ET or Remote Field,

RFT) methods applicable to a variety of tubing applications

such as heat exchangers, furnaces etc in various types of

industries. Typically it provides graded tube layout

depending on the total percentage loss of material on each

tube wall and the results are color coded for easy

reference. The technique used depends on the tube material.

Non-ferromagnetic (with ET)

On

non-ferromagnetic tubes the Eddy Current (ET) method is used

by inserting an EC probe from one end of the tube and

mechanically moving it along the entire tube length. The

method inspects the straight section of the tube and

provides results as percentage of total tube material loss

(e.g. 20-40%, 40-60% etc) per tube. It is capable of finding

general or local material loss, pitting, cracking and dents

on the inspected tube area.

On

non-ferromagnetic tubes the Eddy Current (ET) method is used

by inserting an EC probe from one end of the tube and

mechanically moving it along the entire tube length. The

method inspects the straight section of the tube and

provides results as percentage of total tube material loss

(e.g. 20-40%, 40-60% etc) per tube. It is capable of finding

general or local material loss, pitting, cracking and dents

on the inspected tube area.

Reporting method with color coding for material loss.

Characteristics of the ET technique

-

High speed method. Inspects 500-800, 10m tubes per day.

-

100% inspection of the tube.

-

Little surface preparation (cleaning).

-

Color coded reporting for convenient results overview.

Ferromagnetic (with RFT)

On

ferromagnetic tubes the Remote Field (RFT) method is used by

inserting an RFT probe from one end of the tube and

mechanically moving it along the entire tube length. The

method inspects the straight section of the tube and

provides results as percentage of total tube material loss

(e.g. 20-40%, 40-60% etc) per tube. It is capable of finding

general or local material loss and cracking on the inspected

tube area. It is not suitable for finding pitting.

On

ferromagnetic tubes the Remote Field (RFT) method is used by

inserting an RFT probe from one end of the tube and

mechanically moving it along the entire tube length. The

method inspects the straight section of the tube and

provides results as percentage of total tube material loss

(e.g. 20-40%, 40-60% etc) per tube. It is capable of finding

general or local material loss and cracking on the inspected

tube area. It is not suitable for finding pitting.

Characteristics of the RFT technique

-

High speed method. Inspects about 200, 10m tubes per day

depending on frequency.

-

100% inspection of the tube.

-

Little surface preparation (cleaning).

-

Color-coded reporting for convenient results overview.

Additionally, both methods provide permanent inspection data

recording and storage for future reference. Within the

framework of Envirocoustics’ quality control system, apart

from the quality control documents, test data integrity is

assured and data records and complete technical reports are

provided.

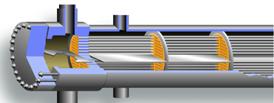

Typical tube inspection system

Cut-out view of tubing and baffle plates.

Envirocoustics also provides

automated UT tube

inspection services and Eddy Currents welds inspection

services.