ACOUSTIC EMISSION THEORY

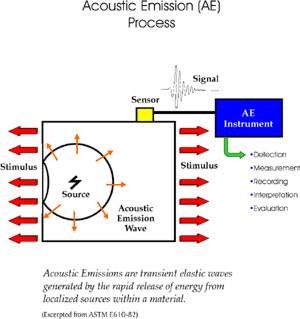

Acoustic Emission, according to

ASTM, refers to the generation of transient elastic waves during

the rapid release of energy from localized sources within a

material. The source of these emissions in metals is closely

associated with the dislocation movement accompanying plastic

deformation and the initiation and extension of cracks in a

structure under stress. Other sources of Acoustic Emission are:

melting, phase transformation, thermal stresses, cool down

cracking and stress build up.

The Acoustic

Emission NDT technique is based on the detection and conversion of

these high frequency elastic waves to electrical signals. This is

accomplished by directly coupling piezoelectric transducers on the

surface of the structure under test and loading the structure.

Sensors are coupled to the structure by means of a fluid couplant

and are secured with tape, adhesive bonds or magnetic hold downs.

The output of each piezoelectric sensor (during structure loading)

is amplified through a low-noise preamplifier, filtered to remove

any extraneous noise and furthered processed by suitable

electronic equipment.

The

instrumentation of Acoustic Emission must provide some measure of

the total quantity of detected emission for correlation with time

and/or load.

Applications

-

Laboratory &

R&D studies

-

In field inspection

-

Structural integrity evaluation

-

Vessels testing [ambient, hot or cryogenic, metallic

and FRP, spheres]

-

Tank bottom testing

-

Nuclear components inspection (valves, lift beams,

steam lines)

-

Corrosion detection

-

Pipeline testing

-

Transformers testing (Partial Discharge)

-

Railroad tank car testing

-

Tube trailers & high pressure gas cylinders

-

Reactor & high energy piping testing

-

Aging aircraft evaluation

-

Advanced materials testing (composites, ceramics)

-

Production quality control

-

Rocket motor testing.

Acoustic Emission for Laboratory Testing

Acoustic Emission

inspection is a powerful aid to materials testing and the study of

deformation, fracture and corrosion. It gives an immediate

indication of the response and behavior of a material under

stress, intimately connected with strength, damage and failure.

Acoustic Emission is used also for monitoring chemical reactions

including corrosion process, liquid solid transformations, phase

transformations.

Acoustic Emission IN FIELD TESTING

Many codes and

standards exist for Acoustic Emission testing of vessels, from

transportation gas cylinders and railroad tanks to thousands tons

storage tanks. Because only active defects and deterioration

produce Acoustic Emission no time is wasted on inactive defects

which are not threatening structural integrity.

Global monitoring- 100% Inspection of the structure

A major advantage

of Acoustic Emission inspection is that does not require access to

the whole examination area. E.g. for covering a total area of a

16m-diameter sphere 30-40 sensors are needed. Thus, the cost of

the test is significantly less than inspection with conventional

NDT methods (for 100% inspection and scanning of the whole area).

Identified problem areas can be inspected using conventional NDT

methods.

Testing with insulation /high temperature processes

In cases of

insulation, only small holes in insulation are required for

sensors mounting, resulting in more cost savings. In cases of high

temperature processes, wave-guides are used to guide the Acoustic

Emission waves from the hot surface to the edge where the sensor

is mounted. Finally, in large cryogenic vessels, permanent sensors

are mounted under insulation for periodic inspection control.

On-line testing

As the method

records defects in real time, it offers the possibility of on-line

inspection, e.g. during hydrostatic testing. Other types of

on-line stress application are introducing of gas into the upper

vapor space, temperature control etc.

Rapid inspection

The actual

Acoustic Emission test takes a matter of hours, and, in some

cases, even less. There is no comparable technique which can

provide 100% volumetric inspection.

Cost Reduction

The use of

Acoustic Emission results in considerable reduction in plant

maintenance costs, while increasing the available information

about plant integrity. Plant downtime for inspection is also

minimized.

Permanent recording of test

Acoustic Emission

data are digitized and stored on a PC, providing permanent

recording of the test to be used at any time for re-evaluation and

post processing analysis.

Defect Location

When more that

one sensors are used, Acoustic Emission source can be located and,

thus, the defective area. Location is based on the wave

propagation principles within the materials and is effectuated by

measuring the signal's arrival time to each sensor. By comparing

the signal's arrival time at different sensors, the flaw’s

location can be defined through triangulation.

Linear location

is used on long gas cylinders, planar (2-dimensional) location for

thick walled and gas filled vessels, while 3-dimensional location

is used for power transformers and concrete structures.

ADVANTAGES

Compared to

conventional inspection methods the advantages of the Acoustic

Emission technique are:

-

High

sensitivity.

-

Early and rapid

detection of defects, flaws, cracks etc.

-

Real time

monitoring

-

Cost Reduction

-

Defective area

location: only critical defects provide sustainable Acoustic

Emission sources.

-

Minimization of

plant downtime for inspection, no need for scanning the whole

structural surface.

-

Minor

disturbance of insulation.

-

Application of Artificial Intelligence (AI) and Technological

Packages: Expert systems for evaluating the condition of

metallic pressure systems and tank bottoms based on the acquired

experience of a huge number of tests are world wide used.